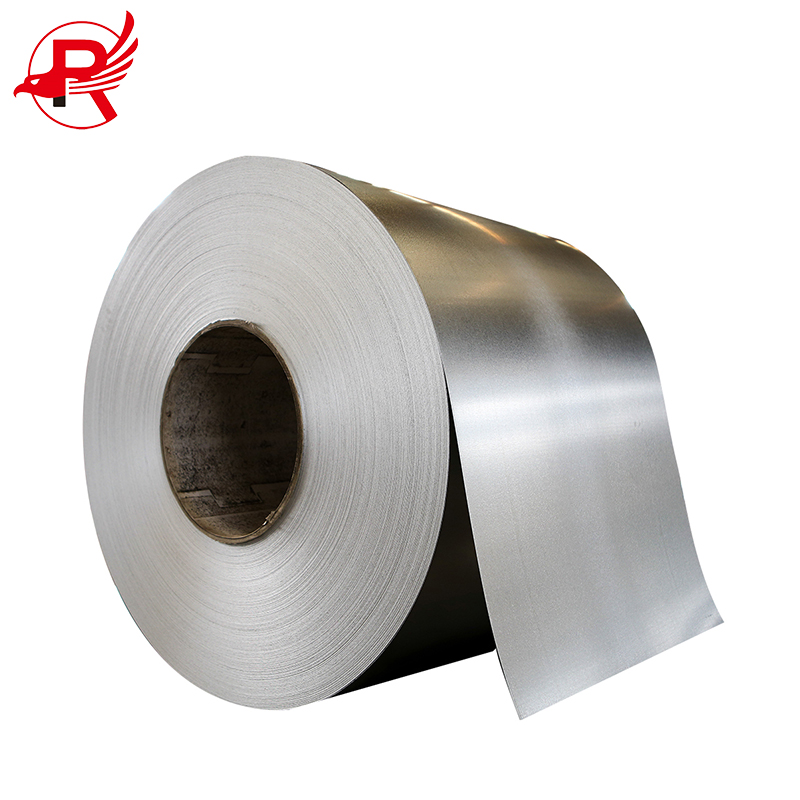

Héichqualitativ G250+AZ150 Aluzink Galvalume Stol Coil

| Produktnumm | DX51D AZ150 0,5 mm Déckt Aluzink/Galvalume/Zinkaluminium Stol Coil |

| Material | DX51D/ 52D/ 53D/ 54D/ 55D/ DX56D+Z/ SGCC |

| Décktberäich | 0,15 mm - 3,0 mm |

| Standardbreet | 1000mm 1219mm 1250mm 1500mm 2000mm |

| Längt | 1000mm 1500mm 2000mm |

| Spulenduerchmiesser | 508-610mm |

| Spangle | Normal, null, miniméiert, grouss, Skin Pass |

| Gewiicht pro Roll | 3-8 Tonnen |

| Produktnumm | Galvalume Stolspiral |

| Material | Kaltgewalzt Zink-Alu-Zink waarmgetauchte Stahlroll/Blech |

| Uewerflächenbehandlung | Gefilmt, Prägung, Falten, Dréckerei |

| Standard | DIN GB ISO JIS BA ANSI |

| Grad | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 |

| Mark | CAMELSTEEL |

| Zink/Aluzink-Beschichtung | Zn 40g/km²-275g/km² Alu-Zink 40-150g/km² |

| Gewiicht vun der Spul | 3-5 Tonnen oder no Äre Besoinen |

| Molerei | Primer: 5μm Deckbeschichtung: 7--20μm |

| Réckbeschichtung | 7 --15μm |

| Faarf | Als RAL oder Är Ufuerderung |

| Häert | CQ/FH/Wéi Är Ufuerderung (G300-G550) |

| Uewerflächenbehandlung | Mat Plastikfolie, chroméiert, falteg, matt, dekoréiert, schleift d'Uewerfläch, markéiert. |

| Applikatioun | Bauindustrie, Wandverkleedung, Daachplack, Rolllueden |

Gebaier: Diecher, Maueren, Garagen, Schallisolatiounsmauere, Päifen, Modulhaiser, etc.

Auto: Schalldämpfer, Auspuffrohr, Scheibenwischeraccessoiren, Benzintank, Camionsbox, etc.

Haushaltsapparater: Frigo-Backplane, Gasuewen, Klimaanlag, elektronesch Mikrowellenuewen, LCD-Frame, CRT-Explosiounsséchere Rimm, LED-Hannergrondbeliichtung, elektresche Schrank

Landwirtschaft: Schwäinhaus, Poulethaus, Kären, Treibhausleitungen, etc.

Aneres: Wärmeisolatiounsofdeckung, Wärmetauscher, Trockner, Waassererhëtzer an aner Kamäinleitungen, Uewen, Beliichtung a Leuchtstofflampeschierm.

Notiz:

1. Gratis Proufnahme, 100% Qualitéitssécherung nom Verkaf, Ënnerstëtzung vun all Bezuelmethod;

2. All aner Spezifikatioune vu ronne Kuelestolpäifen sinn no Äre Besoinen verfügbar (OEM&ODM)! De Fabréckspräis kritt Dir vun der ROYAL GROUP.

De Produktiounsprozess vunGalvalume beschichtete Stahlspiralnormalerweis ëmfaasst et e puer Etappen, dorënner:

1. Botzen a Virbereedung: De Prozess fänkt mat der Botzen vun der réie Stahlroll un, fir all Dreck, Ueleg oder Rost ze entfernen. D'Rollen ginn dann gedréchent a mat Chemikalien virbehandelt, fir hir Haftung un d'Beschichtung ze verbesseren.

2. Beschichtung: Déi virbehandelt Spule gi mat enger Mëschung aus Aluminium (55%), Zink (43,5%) a Silizium (1,5%) an engem kontinuéierleche Warmtauchprozess beschichtet. D'Mëschung bilt eng galvaniséiert Beschichtung op Stahloberflächen mat exzellenter Korrosiounsbeständegkeet.

3. Ofkillung: Nom Beschichtungsprozess gëtt d'Spull an enger kontrolléierter Ëmwelt ofgekillt, fir d'Beschichtung auszehärten an hir Adhäsioun un d'Stahloberfläche ze verbesseren.

4. Veraarbechtung: Dann gëtt d'Galvalume-Spull geschnidden, nivelléiert a geschnidden. Si gëtt och op Qualitéit gepréift, fir sécherzestellen, datt se den erfuerderleche Spezifikatioune fir Déckt, Breet an Uewerflächenqualitéit entspriechen.

5. Verpackung a Versand: Déi fäerdeg Galvalume-Spull gëtt dann verpackt a fir verschidden Uwendungen wéi Daachdeckung, Fassadverkleedung an Automobilproduktioun un d'Clienten geschéckt.

Q: Sinn Ua Hiersteller?

A: Jo, mir sinn e Produzent. Mir hunn eis eege Fabréck an der Stad Tianjin a China. Ausserdeem kooperéiere mir mat ville staatleche Betriber, wéi BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, etc.

Q: Kann ech eng Testbestellung fir nëmmen e puer Tonnen kréien?

A: Natierlech. Mir kënnen d'Fracht fir Iech mat LCL-Service verschécken. (Manner Containerladung)

Q: Wann d'Prouf gratis ass?

A: Prouf gratis, awer de Keefer bezilt fir d'Fracht.

Q: Sidd Dir Goldliwwerant a maacht Handelssécherung?

A: Mir siwe Joer Goldliwwerant a mir akzeptéieren Handelsversécherung.